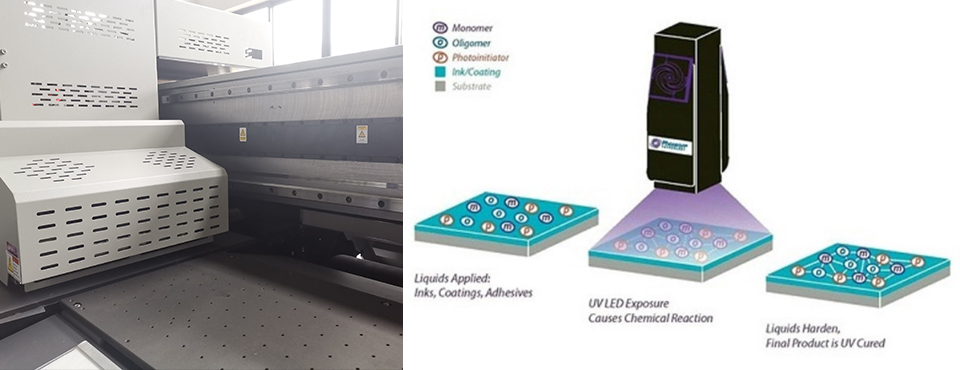

- LED Lamba ve Soğutma Sistemi

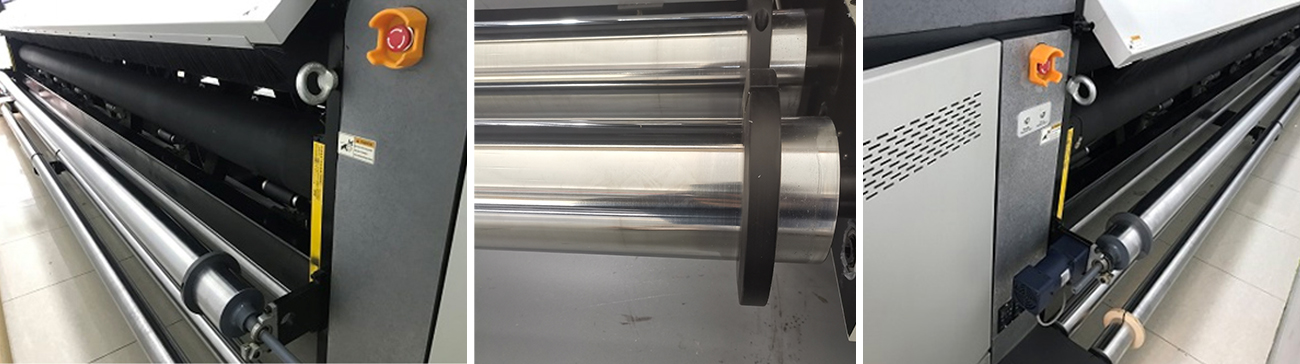

- Rulodan Ruloya Baskı Sistemi

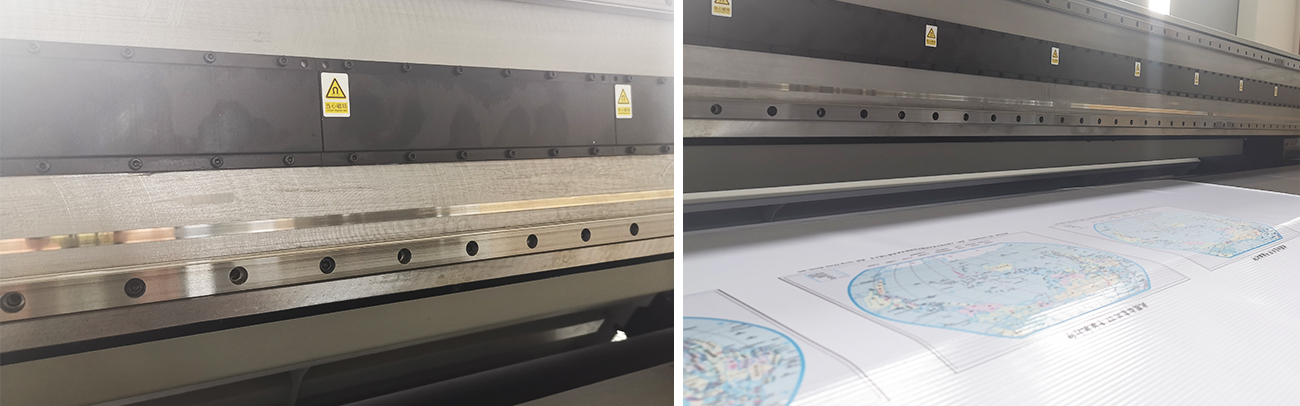

- Geniş Medya Alanı

- Malzeme Açma ve Sarma Sistemi

- Esnek Katman Teknolojisi

- Kullanıcı Dostu İşletim Sistemi

- Medya Kırpma Sistemi

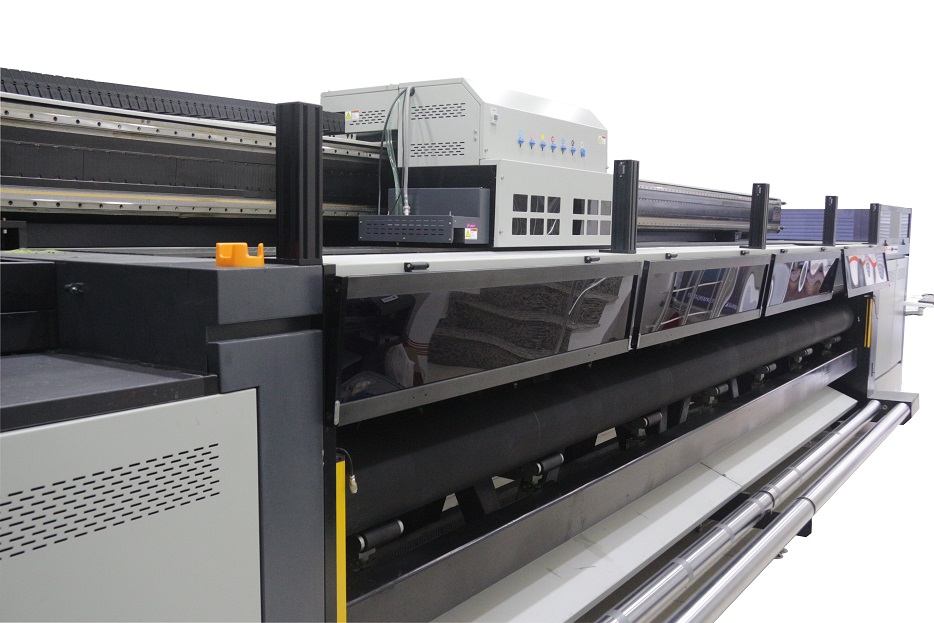

DOCAN UV R5200 Rolodan Ruloya Baskı Makinesi

Yüksek çözünürlüklü yüksek kaliteli piezo electric baskı kafaları ile mükemmel ürünler ve parlak renkler,

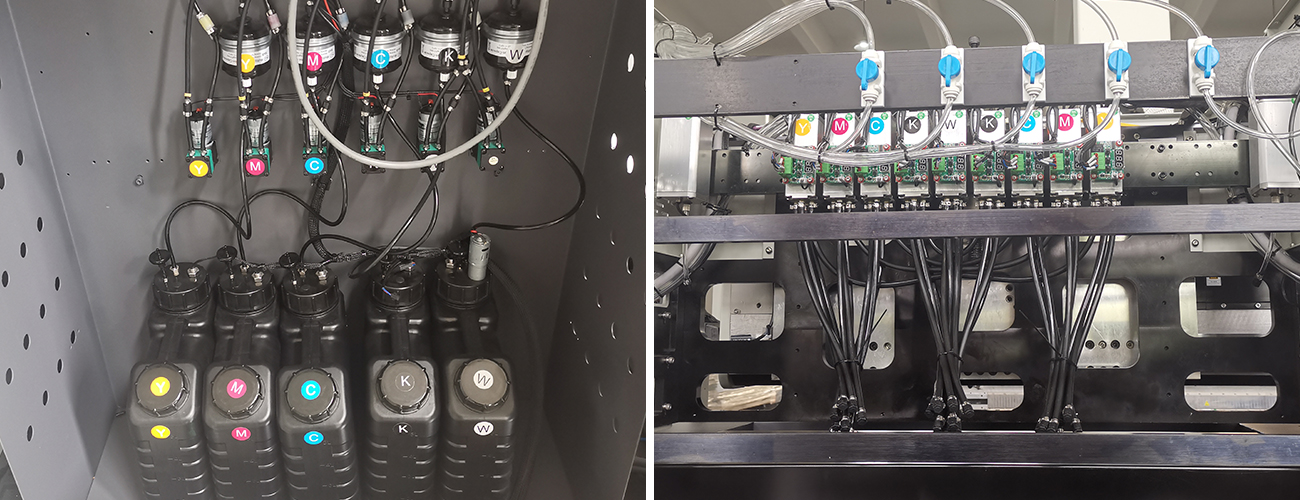

4 renk: YMCK

5 renk: YMCK+W veya YMCK WW

6 renk: Lc Lm Y M C K

7 renk: Lc Lm Y M C K W or Lc Lm Y M C K W W

8 renk: Lc Lm Y M CK W V

VOC ( Uçucu Organik Bileşenli ) UV Mürekkepler ile doğaya ve kullanıcıya dost kokusuz UV Mürekkep

Maximum 520 cm baskı imkanı

Vakumlu baskı alanı ile hertürlü medyaya baskı imkanı

otomatik gerdirilebilir ön toplama sistemi ile zor malzemelere baskı imkanı

Kaset tipe basit değiştirilebilir UV lambalar

Otomatik çarpma sensörleri ile kafalar maximum seviyede korunur

Beyaz kafa opsiyonu ve otomatik boya karıştırma sistemi

Otamatik boya dolum sensörleri

Basit Kullanılabilir arayüz

Ink Curing System

Ink curing system operates with water-cooling Led UV lamps, which is with longer lifetime, more silent operation, never make ozonic gas and emit less heat comparing with traditional mercury lamps. It enables user to have more media choices, printings on sensitive or non-sensitive materials and printings with varnish implementation as well as to save energy,costs and time. With the use of VOC (Volatile Organic Compounds) the UV curable ink is environmental friendly and no bad smell. Drawer-type UV lamp cassette makes it easy to replace the lamps when needed.

MEDIA TRANSFER SYSTEM

Dual roller is for easy loading and transmissioning the media smootly. The position ring keeps madia proper. The maximum material width is 5200mm.

WINDING ROLLER

Industrial take up & feeding system with 2 front, 2 rear durable and long lasting rubber rolls is to open and wrap material before and after printing. Equiped with potentiometer is to adjust the tension level of the releasing and winding rollers during material changes. The rollers are able to forward and reverse due to speed and rotation direction controller. Air compressor connection is required to operate the system.

MAGNETIC GUIDE RAIL

Equipped with Japanese THK silent double guide rail, X axial metal raster and beltless magnetic system ensures straight carriage moving to achieve accurate printing..

PRINTHEAD TRANSPORT SYSTEM

Thanks to the high-precision impact sensors on both sides of the head transport mechanism, the print heads are not damaged from curled, swollen or surged materials.The mechanism has anti-static devices to prevent electrostatic effect that disrupts the image quality.

Ink Supply Unit

Automatic high-volume Ink Supply system ensures continuous printing. The white ink has automatic stirring and circulation system, which avoids the clog of white printhead. The system continuously circulates the ink between Sub Ink Tank, Main tank and internal main tank. It's equipped with Ink low level sensor, which can give users alarm once ink level is below than setting.

Direct Printing

Can print on up to 1-2mm thick flexible medias. The maximum roll media weight is 100kg. Equiped with LED light box is to observe the print quality and status.

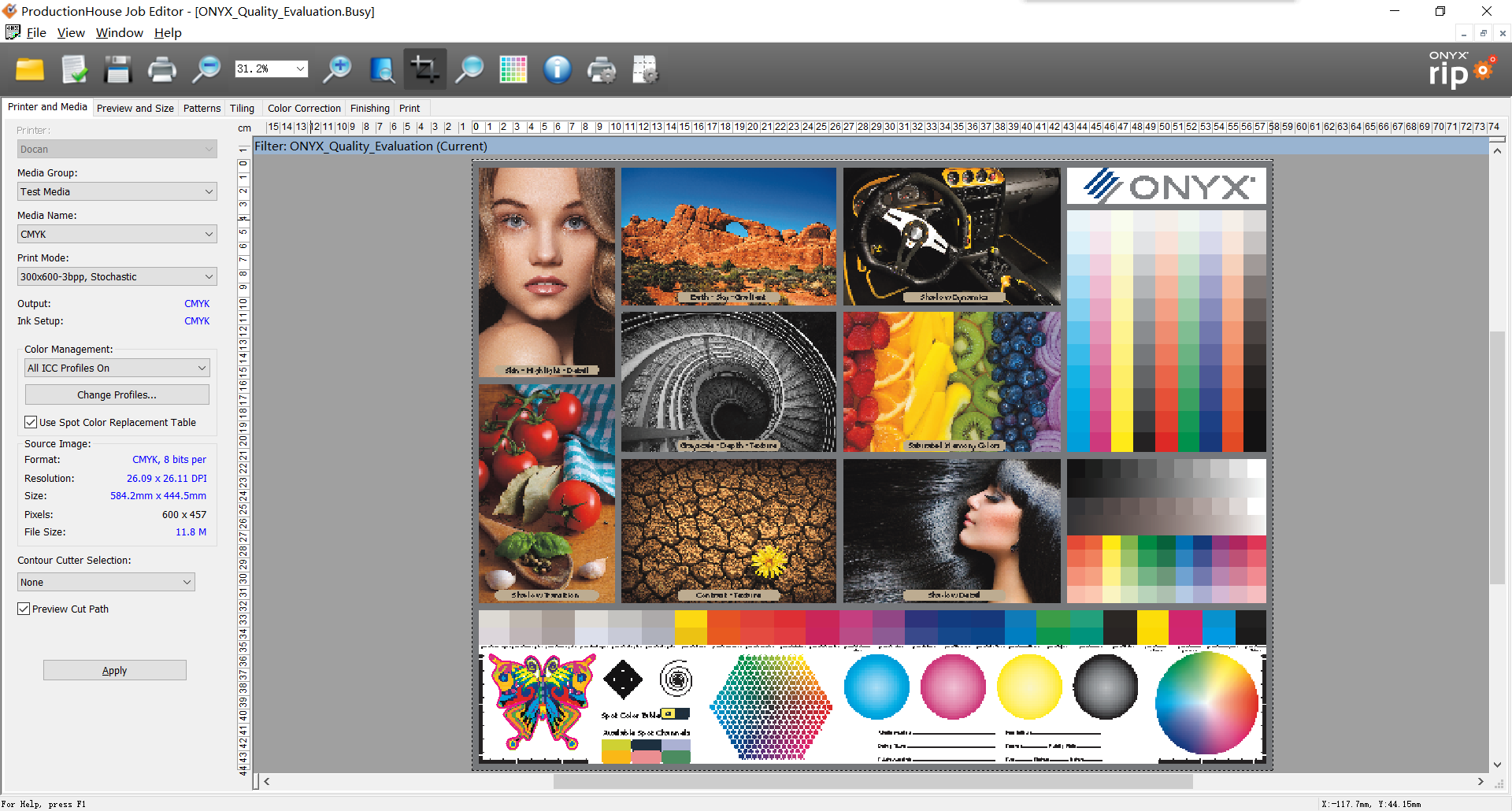

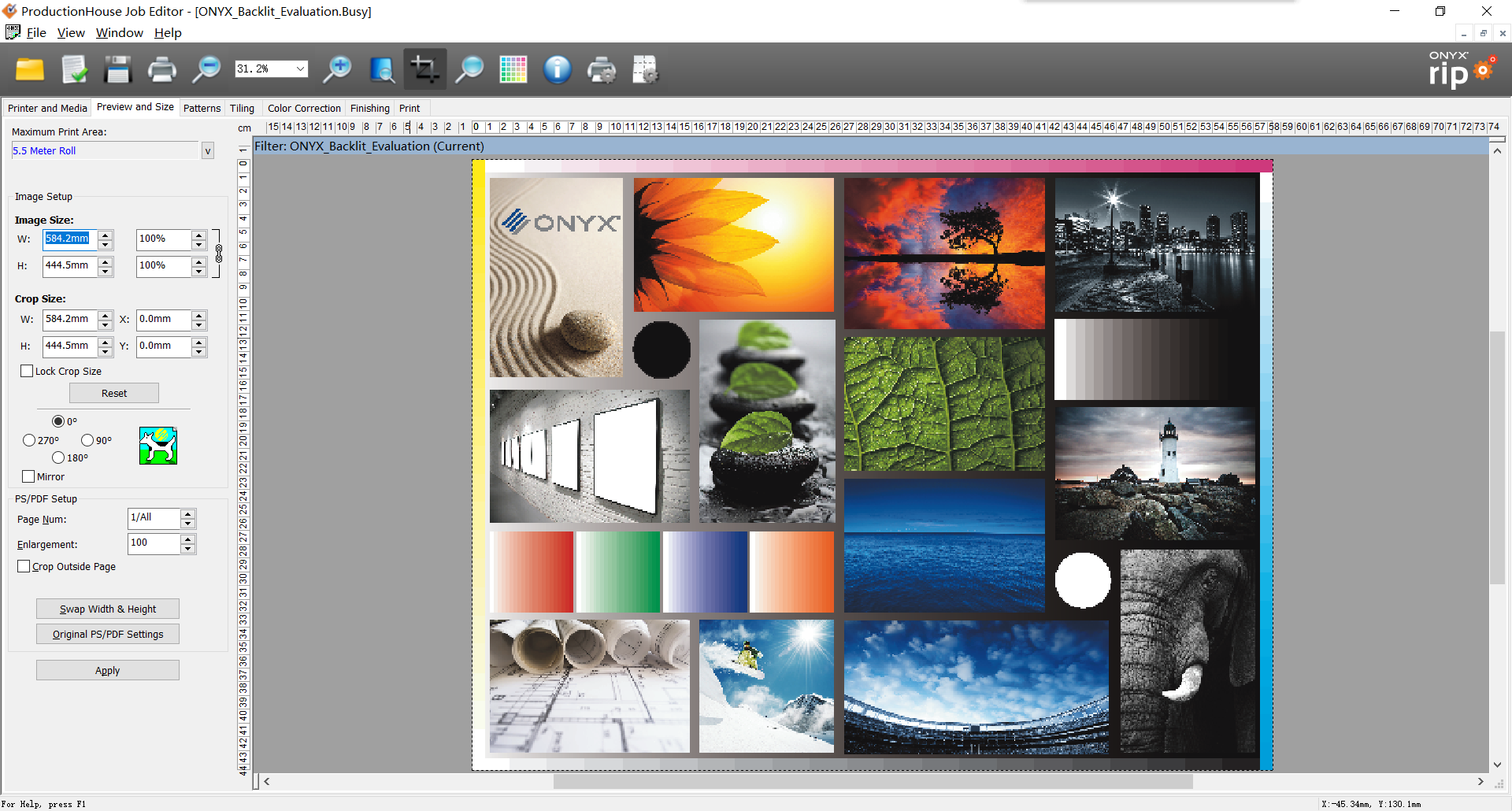

Rip Software

ONYX RIP Center is a standard software for Kyocera engine, which provides the control and simplicity need to get star in wide-format print production and achive consistent high-quality output. The versatile tools in ONYX RIP Center software make it easy to prepare jobs and produce sellable prints faster.

With advanced RIP technology, the user can get smooth gradients, vivid images and very clear small size text. The ICC color management workflow provides vibrant and bright colors.

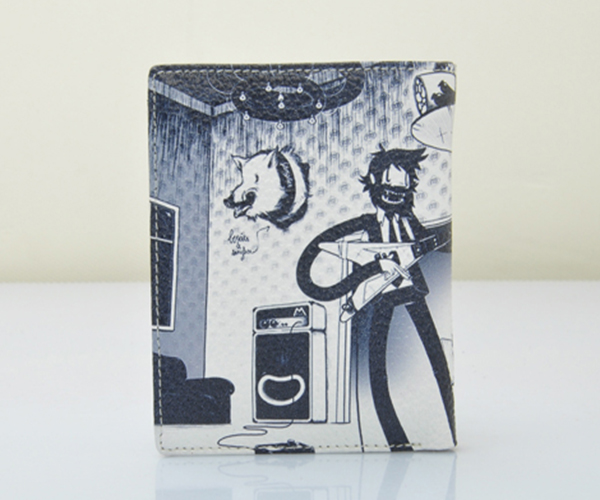

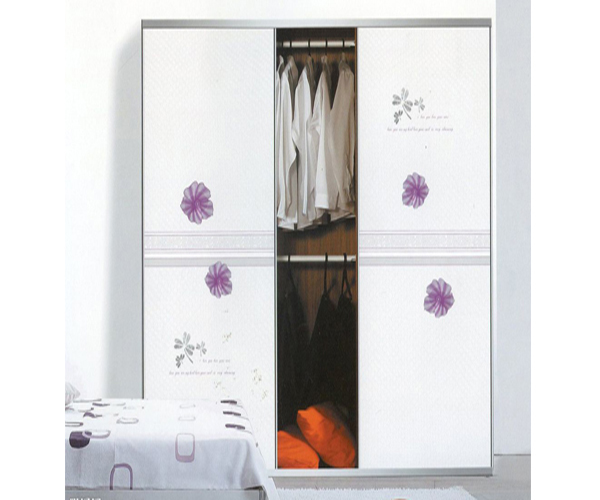

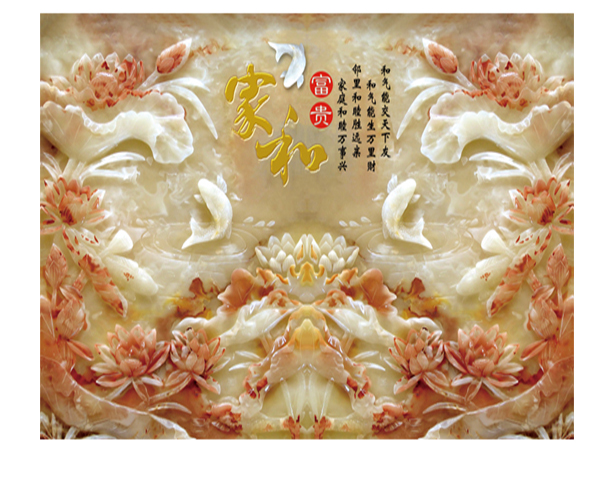

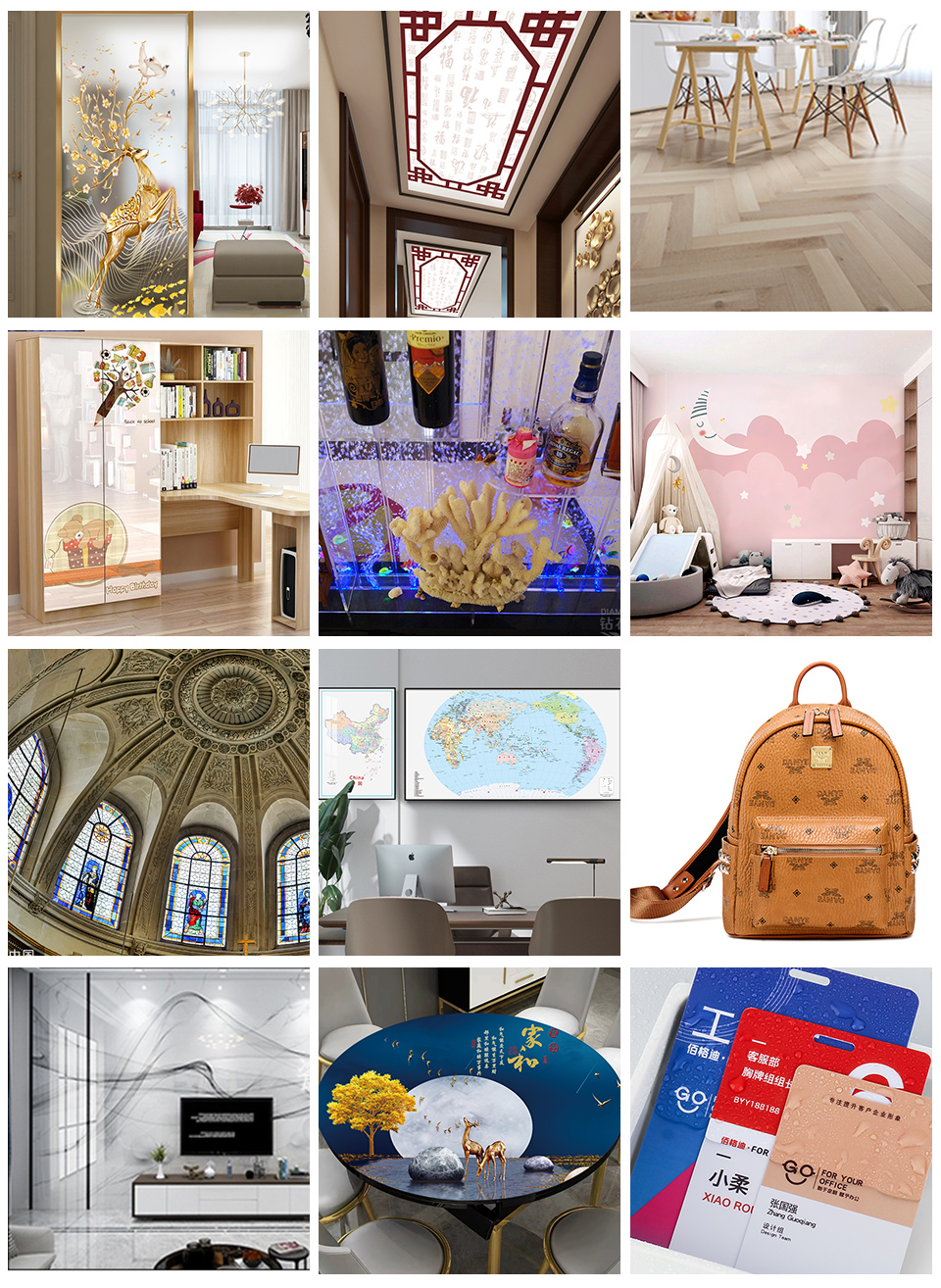

Example Applications

DOCAN · Shanghai

Since 2005

DOCAN UV R5200 MODELİ

KYOCERA KJ4A 3.5 PL / RICOH GEN5 7 PL / KONICA KM1024i 6 PL

Docan UV R5200 Rulodan Ruloya Teknik Özellikler |

|

Baskı Teknolojisi |

Drop-on-demand Micro Piezo Inkjet Teknoloji |

Baskı Kafası |

Kyocera 3.5 Pl. / Ricoh Gen5 / Konica KM1024 i |

Nozzle Sayısı |

2558 Nozzle / 1280 Nozle / 1024 Nozzle |

Damla Büyüklüğü (pl) |

3.5 Pl / 7 pl. / 6 pl. |

Kafa Yüksekliği |

Min: 2.0 mm / Max: 1 cm. |

Medya Özellikleri |

|

Max. Medya Genişliği |

5300xmm Limitsiz |

Max. Baskı Genişilği |

5200xmm Limitsiz |

Max. Medya Yüksekliği |

Maksimum 4 mm. |

* : Baskı kalitesi açısından kafanın Medyadan olan yüksekliği 2-3 mm. olmalıdır. |

|

Rulodan ruloya her türlü malzemeye baskı imkanı |

|

Baskı Hızları |

|

Yüksek Hızlı Modu 4 Adet Kafa |

120 m2/saat Kyocera / 40 m2/saat Ricoh / 60 m2/saat Konica |

Üretim Modu 4 Adet Kafa |

80 m2/saat Kyocera / 25 m2/saat Ricoh / 40 m2/saat Konica |

Kaliteli Modu 4 Adet Kafa |

50 m2/saat Kyocera / 14 m2/saat Ricoh / 25 m2/saat Konica |

* : Baskı hızı DPI seçeneğine göre değişkenlik gösterebilir. |

|

Elektrik Gereksinimi |

|

Baskı Esnasında |

< 360 W |

Beklemede / Stand-by |

≤ 0.5 W / ≤ 60 W |

Güç / Frekans |

AC 100-240 V ± 10 % - 60 or 50 Hz |

Çalışma Ortamı |

|

Sıcaklık |

20°C - 30 °C |

Nem |

40% - 60 % (Yoğunlaşmamış) |

Ağırlık ve Ölçü |

|

Genişlik x Derinlik x Yükseklik |

8500 x 200 x 216 mm |

Ağırlık |

7150 kg |